Environmental

Not listed in CITES. Believed available from well-managed sources.

Distribution

Throughout Europe including the British Isles, extending into Asia and North Africa.

The Tree

Reaches a height of 18m to 30m or a little more depending upon growth conditions which also affect the length of the bole. When drawn up in forests at the expense of their branches, this may be 15m or so in length, but in open situations, the tree branches are much lower down. Diameters are about 1.2m to 2m.

The Timber

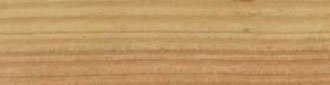

There is no essential difference in the appearance of the wood of either species. The sapwood is 25mm to 50mm wide and lighter in colour than the heartwood which is yellowish-brown. Quarter-sawn surfaces show a distinct silver-grain figure due to the broad rays. The annual rings are clearly marked by alternating zones of early wood consisting of large pores, and dense late wood. Conditions of growth accordingly govern the character of the wood to a great extent. For example, in slowly grown wood the proportion of dense late wood is reduced in each annual growth ring, thus tending to make the wood soft and light in weight. The growth conditions in the various countries that export oak vary considerably. Baltic countries, including northern Poland, produce oak which is generally hard and tough, but further south in Poland, the growth conditions become more favourable to the production of milder, more uniformly-grown oak. The rich black soil of southeast Poland produces the famous Volhynian oak. The character of this type of wood changes a little in countries in Central Europe, such as Czechoslovakia and Hungary, but is generally a little milder in character in Yugoslavia, from whence Slavonian oak is shipped. The weight of oak varies according to type. Oak from the Baltic area, western Europe and Great Britain is about 720 kg/m³ and that from Central Europe is about 672 kg/m³ on average after drying. So-called brown oak is the result of a fungus attack in the growing tree. The fungus, Fistulina hepatica, causes the wood first to assume a yellow colour, then a richer brown or reddish-brown. A yellow-coloured streak sometimes appearing in oak is the result of another fungus, Polyporous dryadeus, but since very few tree diseases persist after the tree is felled, dried timber is no different from normal-coloured wood. Indeed, brown oak is often preferred for its decorative appeal.

Drying

Oak dries very slowly with a marked tendency to split and check, particularly in the early stages of drying and there is a considerable risk of honeycombing if the drying is forced, especially in thick sizes. End and top protection must be provided to freshly sawn stock exposed to sun and drying winds, and sticker thickness should be reduced to about 12mm for stockpiles in the open air during early spring and onwards until winter.

Strength

Both the sessile and pedunculate oaks have well-known and high-strength properties, and those hybrid oaks developed from both types and common throughout Europe are similar in their strength properties. Note: In BS 5268-2: 2002, there is a discrepancy between Tables 7 and 15 regarding characteristic density and strength classes for use in joint design. The values quoted here should be used, rather than those included in the 14 March 2002 edition of the code.

Working Qualities

Medium to difficult. The working and machining properties of oak vary with the mild to tough material which either machines easily or with moderate difficulty. These basic properties are concerned with growth conditions, but they may be exaggerated by indifferent drying methods which allow plain-sawn boards to cup or severe case-hardening to develop, causing excessive wastage in planing and moulding, cupped stock in resawing, and a greater degree of blunting of cutting edges. These must be kept sharpened, particularly where cross-grain is present and especially in planing highly-figured quarter-sawn surfaces where there may be a liability for the grain to tear out at the juncture of the wide ray-figure, thus producing a shelly appearance. In general, oak finishes well from the planer or moulding machine, although in some cases a reduction of the cutting angle to 20° is preferable. The wood can be stained, polished, waxed and glued satisfactorily, takes nails and screws well (except near edges, when the wood should be pre-bored) and also takes liming and fuming treatments well.

Durability

Durable.

Treatability

Extremely difficult (easy for sapwood).

Moisture Movement

Medium.

Abrasions

Very good.

Density (Kg/m³)

720 (Density can vary by 20% or more).

Texture

Medium to coarse.

Use(s)

Heavy structural use, cladding, joinery (interior and exterior), furniture, flooring, sleepers and decking.

Colour(s)

Yellow brown.

10-year guarantee

10-year guarantee Made in Britain

Made in Britain Variety of finance options

Variety of finance options 10+ years' experience

10+ years' experience

page

page page

page